When a customer leaves a review, good or bad, they’re handing you valuable information. Maybe their package showed up late. Perhaps the product was out of stock for weeks. Or everything arrived on time and they’re thrilled.

Whatever they say, that feedback tells you something important about your supply chain. And it’s not just noise. It’s data you can use.

Customer feedback isn’t only for your support or marketing teams. It plays a direct role in how you plan, adjust, and improve your logistics operations. Listening to what customers say can help you spot issues early, fine-tune delivery performance, and avoid costly mistakes.

In this post, we’ll discuss the role of customer feedback in supply chain strategy so that you can meet expectations and not just ship products.

Importance of Customer Feedback in Logistics and Supply Chain

Customer feedback is more than just star ratings – it’s a valuable source of insight for logistics and supply chain decision-making. Let’s break down why customer feedback in supply chain network operations is so important.

Helps Identify Service Gaps

Feedback helps reveal weak links or pain points in your supply chain. For example, if many customers comment that deliveries are slow or packages arrive damaged, these complaints can highlight bottlenecks or inefficiencies in your network.

Addressing these issues early prevents minor problems from becoming significant obstacles, improving the overall service quality.

Enhances Customer Satisfaction and Loyalty

More than 25% of customers switch to a competitor after just one bad customer experience. A single supply chain slip-up, like an item being out of stock, can send customers to another brand. By using feedback to improve, you minimize customer loss.

Moreover, acting on feedback shows customers that you hear them. When buyers feel their voices matter, it builds trust, and they become more loyal.

Drives Innovation and Improvement

Customers often suggest ideas or express needs that can spark innovation. For instance, discussions about delivery speed and convenience might lead a company to explore new solutions like drone deliveries or local pickup lockers.

In this way, feedback can directly impact supply chain strategy by inspiring creative changes. Companies that pay attention to customer needs often discover better processes or technologies to stay ahead of the competition.

Improves Efficiency and Reduces Costs

Customer feedback analysis doesn’t only point out what customers want – it also flags inefficiencies. Complaints about incorrect orders or excessive packaging can drive you to refine warehouse picking processes or adopt better packaging.

Fixing these issues makes the supply chain leaner and more cost-effective. This offers customers a smoother experience while eliminating wasteful practices. As a result, the feedback impacts supply chain performance by streamlining operations that were causing customer pain.

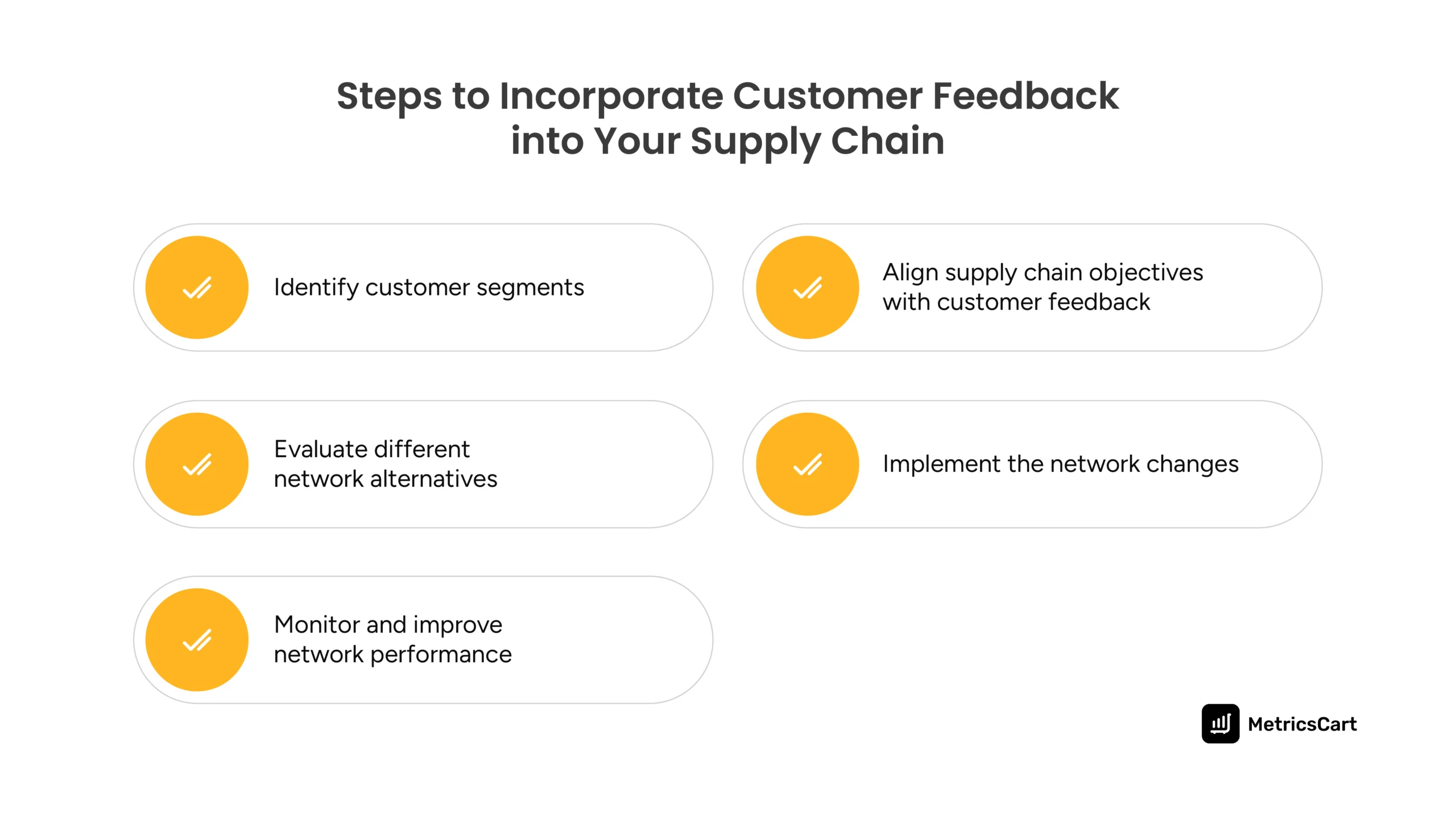

How to Incorporate Customer Feedback into Your Supply Chain Network?

Here’s how to incorporate customer feedback in supply chain network planning in a step-by-step way:

Identify and Understand Customer Segments

The first step is to divide your customer base into key segments and understand each group’s needs and preferences. Not all customers are alike, and different segments may have different expectations.

Use data from surveys, purchase history, and reviews to group customers by factors like location, order frequency, product types, and service expectations. For example, you might identify segments such as urban shoppers who value one-day shipping, budget-conscious buyers who care about cost, or premium customers who expect extra services.

By identifying these segments, you can tailor your supply chain network design for better services. If one segment’s feedback shows they often experience stockouts of a certain product, you can adjust inventory levels or warehouse locations for that segment.

In short, segmenting customers allows you to create targeted logistics strategies so each group feels like the supply chain was built for them.

Align Supply Chain Network Objectives with Customer Feedback

Once you know your customer segments and their needs, the next step is to align your supply chain objectives and metrics to those customer expectations. This means setting goals and KPIs that reflect what customers care about most.

For example, if customers consistently complain about delivery speed, then on-time delivery percentage and delivery lead time become critical metrics to track. If feedback emphasizes product quality upon arrival, you need to focus on damage rate or return rate metrics.

Monitor these metrics regularly and link them to customer satisfaction scores or feedback trends. This alignment keeps everyone focused on what truly matters—meeting customer expectations—rather than just internal efficiency metrics.

READ MORE | Confused About Review Metrics You Need to Track? Dive into Top Review KPIs that Brands Benefit from Using Review Analytics

Evaluate Different Network Alternatives

With customer-centric goals in mind, you can refine the supply chain network by evaluating different network alternatives and seeing how each would impact customers.

For this, you need to consider scenarios and options like opening new distribution centers rather than shipping from a central warehouse, using air freight for faster delivery rather than ground transport for lower cost, or fulfilling online orders from stores to serve specific customer segments.

Use tools like simulations, pilot programs, or A/B testing in select regions to predict how each network change will affect customer metrics. For instance, you could pilot a second warehouse in an area with frequent delivery complaints and see if customer ratings improve there.

By evaluating network alternatives based on customer feedback, you ensure that any changes to your supply chain are better for the customer. Once you are satisfied with the result, choose the network design that best balances cost with the service improvements customers want most.

Implement the Network Changes That Best Align with Your Customer Feedback

After selecting the network design or changes that make the most sense, it’s time to implement them. Start by clearly communicating the changes to your team and partners (e.g., carriers, warehouse managers, suppliers) so everyone understands the customer-centric goals.

For example, if you’re opening a new distribution center to serve the West Coast faster, ensure your logistics partners know that faster delivery is the key objective based on customer feedback.

You can implement the change in phases by beginning with one region or product line, monitoring the results, and then expanding to other areas. This way, you can catch any unforeseen issues early.

As changes roll out, track the impact on your earlier defined KPIs (delivery speed, stock availability, etc.) and see if customer feedback scores (like star ratings or Net Promoter Score) improve. If you’ve aligned things correctly, the metrics should move in a positive direction.

Monitor and Improve Network Performance

Supply chain management is an ongoing process. In this final step, you should collect customer feedback through reviews, surveys, customer service interactions, and even social media comments about delivery or product availability.

Modern supply chain teams use techniques like sentiment analysis and thematic review analysis to sift through large volumes of feedback and spot recurring issues.

In addition, it helps you to be aware of external changes. Customer preferences can evolve, and what delighted them last year might not suffice next year. Competitors might raise the bar with even faster shipping or more convenient return policies, shifting customer expectations. By staying in tune with feedback, you’ll catch these shifts early.

This creates a culture of continuous improvement over time. Your supply chain becomes more agile and resilient because it constantly realigns itself to what customers want.

Conclusion

Today, customer expectations are higher than ever. They want their products faster, fresher, and exactly as promised. Using feedback to optimize your supply chain means you’re not guessing what matters – your customers are literally telling you.

It helps brands pinpoint weaknesses, reduce inefficiencies, and deliver exactly what customers expect. From faster delivery to fewer stockouts, feedback’s impact on supply chain design is clear and measurable.

MetricsCart’s review monitoring software makes this process easier. It helps brands track, analyze, and act on real-time customer reviews across marketplaces, turning raw feedback into actionable insights for your supply chain and digital shelf performance.

Streamline your Supply Chain with MetricsCart Review Analysis.

FAQ

Order delivery reviews, customer service complaints, return reasons, product availability feedback, and post-purchase surveys provide the most actionable insights for logistics and fulfillment improvements.

Yes. Feedback often reveals patterns—like sizing issues, packaging damage, or unclear product descriptions—that lead to returns. Fixing these upstream in the supply chain can lower return volume and cost.

Ideally, weekly or monthly. Frequent review helps you catch trends early, respond before issues scale, and adjust operations in real-time.

It’s typically a cross-functional effort involving operations, logistics, digital shelf managers, and customer service. Many companies also assign a supply chain analyst or digital experience lead to own this task.

Yes. DTC feedback often focuses on delivery, packaging, and service, while retail-related feedback might highlight in-store availability, shelf presence, or bulk packaging problems.